Large stones, or boulders, have long caused problems for NCC’s stone sites. With Microsoft’s AI technology, boulders can now be identified automatically, streamlining the work, reducing costs, and making business fairer for NCC and its customers.

Hundreds of trucks pass through NCC’s stone sites in Greater Stockholm each week, all loaded with stone material from large construction projects. NCC mainly purchases excavation rock from extensive blasting operations, such as the subway expansion.

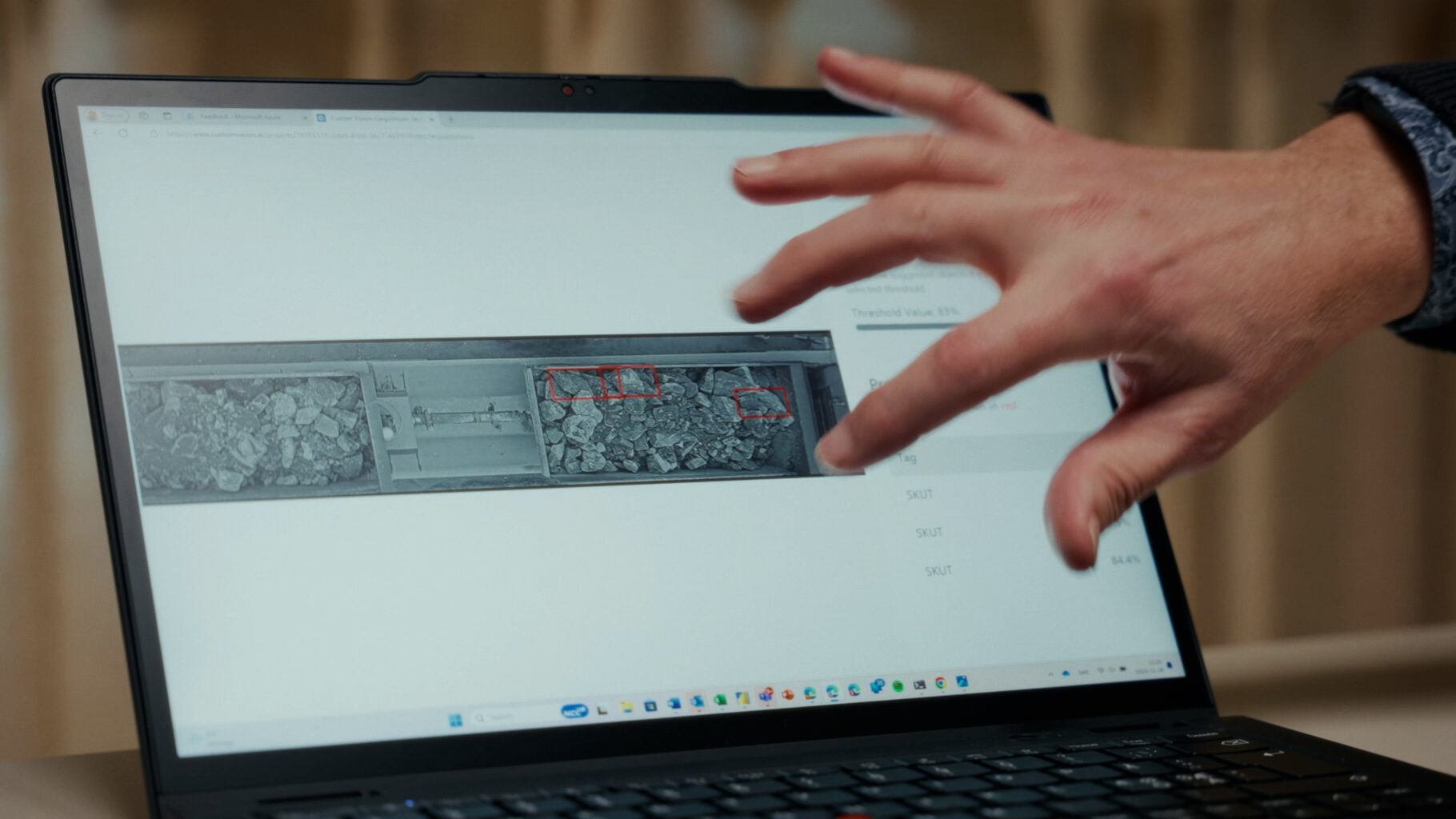

To calculate the cost of the material, the truckloads, which mostly arrive at night, are weighed on a truck scale. A picture of the load is simultaneously taken by cameras installed on the sites.

“The size of excavation rock varies greatly. Some stones are too large to be fed into our crushers during blasting. We call these boulders,” says Stefan Westlén, NCC area manager.

However, the truck scale cannot differentiate between various stone sizes; it just displays a single weight. Therefore, it is up to the truck driver to provide accurate information. Boulders are more expensive to handle because they have to be manually sorted and broken down into smaller stones with an excavator and a stone breaker.

“This is a relatively costly process, and sometimes, there are weighing mistakes, which means the coverage (we charge for receiving boulders) for the costs is missing.”

AI Became the Way Forward for Fair Measurement

Four years ago, Nicklas Bruske, NCC business analyst IT, began exploring the possibility of using Microsoft Azure Custom Vision AI to photograph the stone loads at the various sites.

“There are a lot of images, and the customer center could not possibly review everything manually. With Microsoft’s AI solution, I hoped to streamline the handling of the products,” says Nicklas Bruske, continuing:

“We finally decided that the most feasible approach was to train AI to differentiate between stone products. We started a proof of concept with Microsoft’s help to test how well the technology could recognize two types of stone material.”

The proof of concept was successful, and Stefan Westlén identified NCC’s challenges with boulders and excavation rock. Here was a way to achieve greater fairness in the business by letting AI flag the presence of boulders in a load.

“We saw the potential to get paid fairly but also to ensure our customers receive fair treatment. If the driver reports boulders and the AI later shows it is untrue, we can adjust it so the customer gets better compensation,” says Stefan Westlén.

Real Business Value with Custom Vision AI

Seeing the real business value in the solution encouraged NCC to invest more money when it was time to pilot one of Greater Stockholm’s stone sites.

“In the pilot, we invested in cameras and worked on getting the camera placement right,” says Nicklas Bruske.

Through Microsoft Azure Custom Vision, the AI model was trained on thousands of images of stone material. The model learned to recognize boulders, and NCC then used the model’s prediction (the percentage of certainty that it has found a boulder) to flag potentially incorrectly registered products.

“A high percentage indicates that boulders are likely present in the load. This is compared with the driver’s reported information, and we mark the transactions for the customer center to review for potential errors.”

This created a whole new level of insight into NCC’s operations. The solution has now been implemented at five of the ten stone sites in Greater Stockholm. Today, the technology automatically flags incoming stone material that is likely registered as the wrong product to pass on to NCC’s customer center.

“The customer center staff can now handle the work in a way that would have previously required significantly more resources. The data we collect also allows us to make smarter, more accurate decisions. This is something NCC generally works with, and this is a clear example of how it creates business value.”

Lower Costs with Fewer Boulders

Another effect identified by NCC is that customers now send in fewer boulders.

“Now they know it is more expensive for them to send boulders, fewer boulders are arriving. This means our costs are reduced because we do not have to handle and break down as many boulders,” says Stefan Westlén.

NCC is currently calculating the exact financial impact, but Stefan Westlén is confident:

“It provides positive business value. The sum of the effects—fairer pricing, reduced handling costs, better customer dialogue, and a more efficient way of working for the customer center—really makes the technology profitable.”

Multiple Future Uses

“Using the trained model to find boulders at the Greater Stockholm stone sites is just the beginning. We will train more models to identify other things on the loads,” says Nicklas Bruske.

“We have standardized the camera placement—right in front of the scale, directly above, twelve meters up—so the solution can easily be rolled out to more sites.”

Stefan Westlén concludes:

“The hardware and platform are in place. Potential further uses include differentiating between expensive and cheaper products and identifying trash, blasting debris, or asphalt blocks. The possibilities of creating business value in other areas of our operations are great with the new AI technology.”