“In our industry, the stakes are high. If one of our machines were down for a day, the cost for a chipmaker could run into the millions.”

Working under pressure is something that Michiel Haverkorn Van Rijsewijk has grown used to since he started as the Director of Customer Support at ASML in February 2020. Within a month of starting at the world’s largest semiconductor lithography equipment maker, the company’s long-established way of working was turned upside down with the outbreak of COVID-19.

Thankfully, the company had already been investigating the potential of mixed reality (MR) technologies to optimize remote support to its customer base, which includes all of the world’s top chipmakers.

“Our R&D team had been working on a long-term roadmap for mixed reality technologies for some time,” says Peter Peusens, Head of Customer Support for DUV Operations at ASML. “So when the COVID-19 outbreak hit, we could quickly form a cross-sector team to align on potential solutions, while we agreed with customers on a way to implement the solutions in this time of crisis.”

As an innovation leader in the chip industry, ASML is a company where long-term planning and decisive company-wide action has to happen at the same time. It moved fast to start using HoloLens 2, Microsoft Dynamics 365 Remote Assist and Microsoft Teams across its network. It has allowed them to continue to service their clients’ machines during the COVID-19 crisis and it has opened the door to a new way of working for ASML and the chip industry.

The biggest tech company you’ve never heard of

“Semiconductor technology is all around us,” says Sander Hofman, Spokesperson and Communications Manager at ASML. “It’s in our computers, in our phones, in our streetlights and bank cards. And 80% of all the chips in the world are made on ASML machines.”

As the world’s largest machine maker for semiconductor lithography, Dutch company ASML employs almost 25,000 people globally, with around 13,000 of its employees working from the company’s headquarters in Veldhoven, Netherlands.

“We like to talk about ourselves as the biggest tech company you’ve never heard of,” says Hofman.

The company’s chip-making machines are “the size of buses,” according to Hofman – complex machines that sit at the centre of their customers’ ‘cleanrooms’ – spaces designed to maintain extremely low levels of particulates that can interfere with the 24/7-production of semiconductor chips.

With some of the biggest names in tech as their clients, there are billions of dollars’ worth of technology, expertise and intellectual property built around ASML’s machines globally.

Traditionally, that has limited the tools ASML’s engineers can use when visiting their clients’ cleanrooms for the purposes of machine installation, maintenance or updates.

Using MR to keep chip production going

“You don’t just walk in and out of a cleanroom,” explains Haverkorn Van Rijsewijk. “It is a complicated process just to enter the space. So when our engineers visit our clients’ cleanrooms, they aren’t able to bring a phone or computer in with them because the companies we work with are extremely sensitive around their IP.”

But when restrictions on travel suddenly prevented ASML’s engineers from visiting their customers’ cleanrooms in-person, it was in everyone’s interest to find a solution that would allow work on ASML’s pivotal machines to continue remotely.

“To not allow remote support at that time would have meant days if not weeks of delay and machine downtime, which of course would have meant lost revenue for our customers.”

And with many of their clients seeing an upsurge in demand for their tech products – containing chips made on ASML’s lithography systems – as people were forced to stay home across the world, finding a solution became a pressing necessity.

That solution was HoloLens 2 – Microsoft’s latest MR headset.

Enabling remote maintenance with HoloLens 2

“We’re pretty used to managing crises at ASML because our customers want our technology as early as possible, often when it’s still in development,” says Peusens.

“We work together to mature the technology and that means we know how to deal with difficult situations as they arise: we set up crisis teams.”

That is exactly what ASML did to bridge the gap between its semiconductor experts and its customers’ cleanrooms. “Building on the exploratory R&D work that had been done in previous years, we realised that we could quickly implement a mixed reality solution with HoloLens 2 because of its integration with our other Microsoft services,” Peusens explains.

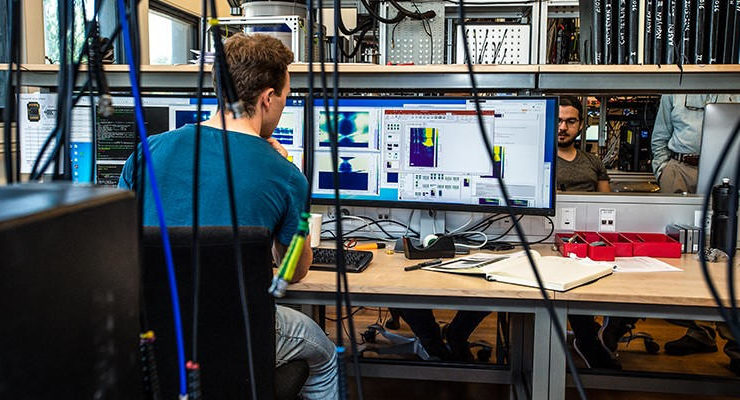

“So we established a Task Force that communicated via Remote Assist and Microsoft Teams, to test the MR technology in our own lab in the Netherlands.”

The test was successful, allowing an engineer wearing a HoloLens 2 headset to enter ASML’s cleanroom alone, while an expert assisted remotely using Microsoft Dynamics 365 Remote Assist and Microsoft Teams. Together these applications gave the expert real-time audio and visual contact with the engineer wearing the headset in the field – enabling them to view objects in mixed reality and offer guidance and solutions when needed.

The benefits of mixed reality

“Chipmakers’ policies on IP have meant it’s been difficult to convince them to adopt mixed reality technology in the past,” says Haverkorn Van Rijsewijk. “So, the key thing for us as a company was to demonstrate the value for them to use this technology in this time of crisis.”

For Haverkorn Van Rijsewijk, there are several key benefits that make the case for the use of mixed reality next to the regular services offered by ASML’s skilled engineers in the field.

“The first and most important benefit is that it can transport knowledge across the world in an instant,” he says. “If a field engineer needs over-the-shoulder support from an expert, MR is a powerful bridging solution. Real-time instructions and verbal comments help to do things right first-time.

“The second benefit has to do with speed and response time,” adds Haverkorn Van Rijsewijk. “Usually, if you go through a support escalation, it can take 24 to 48 hours before the expert is actually in the customer’s cleanroom on the other side of the world. With MR, we are able to respond much more quickly, effectively offering 24/7 service provision. Lastly, it can also help to reduce travel hours and the associated costs.”

These are benefits that ASML’s customers are starting to experience themselves: the company now has 75 HoloLens 2 headsets deployed globally.

A mixed reality roadmap for the future

“The current situation is not nice for anyone,” says Haverkorn Van Rijsewijk, reflecting on the ongoing restrictions resulting from the COVID-19 outbreak. “But an unexpected outcome is that it has allowed ASML to make fast progress in the area of remote support. What was originally a three-year roadmap became something that we could implement in just one month.”

Feedback from the engineers using HoloLens 2 has been positive and Haverkorn Van Rijsewijk and his team have established an ongoing learning platform with lessons on how to best use the MR headsets in customers’ cleanrooms.

“We’re still very much at the beginning of our MR journey,” says Haverkorn Van Rijsewijk. “Without Microsoft’s existing integration between services and hardware, the rollout of a solution this quickly to such a wide variety of customers and users would have been impossible.

“Now we want to work with other players in the industry to define a standard that we can all adopt,” he explains. “If we manage to develop that roadmap together, then I believe there’s huge potential for growth and impact in the industry beyond the current situation.”