At the start of 2020, there were all manner of manufacturing topics to be discussed. And then suddenly, there was only one.

It would be difficult to overstate the impact of Covid-19’s disruption on manufacturers. Almost across the board, this industry has seen supply chains breaking, cash ceasing to flow and production lines grinding to a halt.

So it’s unsurprising that the coronavirus outbreak has taken up the whole bandwidth of industry thought, writing and discussion for the last few months.

What’s especially interesting though, is the fact there are marked parallels between the most critical topics both pre-crisis and today. Much of the technology being examined now – in terms of helping the manufacturing sector to adapt, recover and become more resilient – is the same technology that was discussed at the start of the year in the context of driving efficiency, sustainability and innovation.

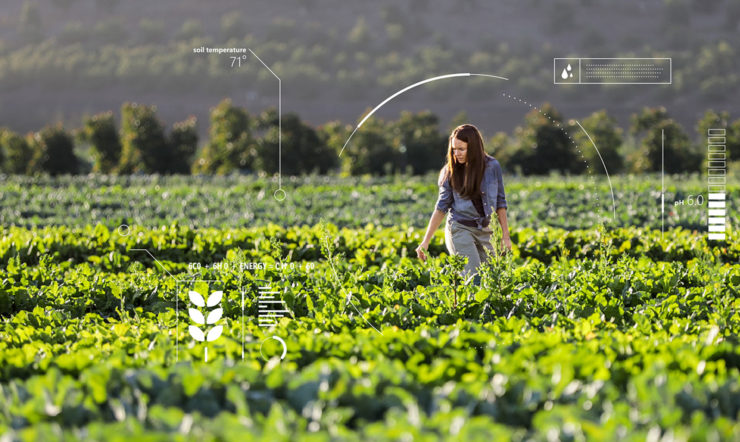

Transforming supply chains with IoT, AI and automation

Indeed, digital transformation almost always delivers continuous, evolving and sometimes unexpected benefits to an organisation. It’s rarely a single solution to a single problem. In fact, the most important advantages often turn out to be those that were barely considered when the process was initiated.

Take supply chain optimisation. Many customers use our technology to tame the near-overwhelming complexity of their supply chains. With a combination of IoT and other innovations, we help them to map their whole ecosystem in real time, and use AI to make decisions faster and more accurately. Up till a few months ago, this was chiefly for purposes of financial, logistical and environmental efficiency. But since the mass disruption to the global economy, it’s become a matter of business continuity, and in some cases, even survival.

In the same way, industry leaders agree that 2020/2021 will see a great acceleration in digitalisation initiatives like smart factories, connected product innovation, remote controls and above all: automation.

Manufacturing through the COVID-19 crisis

The following articles were written by different subject matter experts from Microsoft. And they straddle the difficult, yet fascinating period from pre-outbreak to lockdown, through to the present day, when societies are taking cautious steps back to normality.

In this article, which was written before the coronavirus outbreak, Max Tchapeyou explains why manufacturing needs to focus on workforce transformation. And why now is the perfect time to attract younger and more diverse talent.

In another ‘pre-outbreak’ article, Patrick Van Loon explains why manufacturers get stuck in ‘pilot purgatory’ with AI and ML projects. And he draws lessons from Henry Ford’s ground-breaking production line for how to escape it.

There’s a highly relevant article by Valerio Frediani, who talks to Koen Groothaert from steel wire manufacturer, Bekaert, about a project called ‘Digital Way of Working’. It’s about introducing Smart Manufacturing Apps, which will have actually proven invaluable since the coronavirus outbreak.

Roger Mueller on connected product innovation is equally essential reading. He sets out in detail how manufacturers can continue innovating while engineers across a distributed process remain at home.

Elsewhere, Christoph Pawlowski describes how stainless steel manufacturer, Outokumpu, is using Microsoft technology to become greener, much of which will have helped them be more resilient too.

And lastly, Christoffer Sundgren talks to Mathias Johansson from Swedish cutting-tool manufacturer, Sandvik Coromant, about why partnership and collaboration are helping them overcome challenges in these disruptive times.